Txheej txheem cej luam

CNC tshuab cuab yeej yog kev sib koom ua ke ntawm kev siv tshuab, hluav taws xob, hydraulic, pne-umatic, microelectronics thiab cov ntaub ntawv thiab lwm yam thev naus laus zis ua ib qho ntawm cov khoom siv hluav taws xob sib xyaw ua ke, hauv cov cuab yeej tsim khoom siv nrog hloov pauv, universal, high-precision, siab- efficiency " yoog raws" cov khoom siv tsis siv neeg ntau lawm, nws yuav ua tiav ntau yam kev ua haujlwm thiab cov kauj ruam uas yuav tsum tau ua thiab cov duab thiab qhov loj ntawm workpi-ece, nrog cov lej digital, Los ntawm kev tswj nruab nrab rau hauv cov khoom tswj cov lej, cov lej tswj cov khoom siv rau cov ntaub ntawv nkag. kev ua haujlwm thiab kev suav, kev tswj hwm lub tshuab cuab yeej thiab cov khoom siv tsav tsheb, kev ua haujlwm tsis siv neeg ntawm qhov yuav tsum tau ua haujlwm. Cov txheej txheem ntawm CNC tshuab cov cuab yeej thiab nws cov feem pua ntawm cov zis thiab tag nrho cov tswv cuab ntawm cov cuab yeej siv hlau txiav tshuab yog ib qho tseem ceeb qhia kom paub tseeb tias tag nrho cov theem ntawm kev lag luam hauv lub teb chaws thiab kev tsim khoom ntawm ib lub teb chaws. Nyob rau hauv xyoo tas los no, qhov sib koom ntawm CNC tshuab cuab yeej hauv Suav lag luam tau nce ntau xyoo los ntawm lub xyoo, thiab nws tau siv ntau dua hauv cov lag luam loj thiab nruab nrab, thiab nws kuj yog feem ntau siv hauv cov lag luam me thiab nruab nrab thiab txawm tias cov lag luam ib leeg.

CNC lathe txheej txheem yuav tsum

- Thaum lub workpiece ua tiav los ntawm CNC tshuab dhos, tus nqi pub yog loj, qhov kev ua haujlwm-ssing ceev yog tsawg, thiab cov txheej txheem machining muaj feem cuam tshuam vim qhov tsis sib xws ntawm qhov chaw ua haujlwm.

- Lathefinishing, tus nqi pub me me, txhawm rau kom ua tiav kev ua haujlwm, kev ua haujlwm ceev yog siab.

- Lub spindle lub cev muaj zog yuav tsum muaj tsawg ceev thiab siab torque tso zis, thiab stab-le, thiab muaj peev xwm khiav ntawm kev kub ceev.

- Txais cov teeb liab analog yuav tsum muaj siab linearity thiab qis load cuam tshuam.

- Themotor suab nrov yog me me, thiab qhov cuam tshuam rau cov khoom siv automation yog me me. Ceev thiab ceev kom tsawg li sai tau.

Qhov zoo ntawm CNClathe KD600 series khoom

Kd600 series high-performance vector inverter adopts advanced flux control technology, lub cev muaj zog torque ntawm tsawg ceev yog loj, ceev ceev yog siab, tus nqi yog tsim nyog, muaj nuj nqi yog ua tiav, nrog instantaneous hwj chim tsis ua hauj lwm thiab ceev nrhiav thiab pib dua muaj nuj nqi. , kom paub meej tias lub kaw lus kom ua tiav kev ua haujlwm tas mus li, kom ntseeg tau tias lub cev muaj zog khiav ntawm lub xeev ua haujlwm siab tshaj plaws, yog li ntawd, Siv KD600 series high-performance vector inverter es tsis txhob spindle AC servo system yog qhov kev xaiv zoo tshaj plaws rau kev lag luam tshuab. KD600 series inverter muaj cov hauv qab no nta:

- Tsis muaj zog sib nqus tswj tshuab: tuaj yeem tswj tau zoo ntawm qhov tsawg zaus loj torque lub cev muaj zog, tuaj yeem khiav hauv 0 ~ 600Hz.

- Fastandstable nres ceev: sib nqus flux deceleration nres tshuab tuaj yeem ua rau lub cev muaj zog thiab nres hauv lub sijhawm luv.

- Kev nrawm nrawm thiab ruaj khov: qhov linearity ntawm qhov chaw ceev yog qhov zoo, qhov tseeb ntawm kev ruaj ntseg ceev yog siab, thiab qhov hloov pauv ntawm qhov ceev yog nyob rau hauv 5/1000 thaum lub load hloov.

- Kev ua tau zoo tsawg zaus: Optimized PG-free vector tswj algorithm, tsawg zaus 1Hz mus txog 150% cov zis torque, los xyuas kom muaj zog txiav quab yuam thaum ua tiav.

- Muab ntau zaus input hom: 2 qhov chaw voltage 0 ~ 10V lossis -10V rau +10V input, 1 qhov tam sim no 4 ~ 20mA lossis 0 ~ 20mA input.

- Daim ntawv thov dav dav ntawm daim phiaj hluav taws xob: Kev hloov pauv hloov hluav taws xob siab tshaj plaws tuaj yeem siv rau ntau qhov chaw ib puag ncig.

- Exquisite ntau lawm txheej txheem: txais yuav ib tug tshwj xeeb txheej txheej thickening txheej txheem, cov pa duct yog kiag li cais tawm ntawm lub sab hauv PCB, thiab muaj zog adaptability rau lub cev hnyav ib puag ncig xws li hlau plua plav, corrosive gas, thiab av noo.

- Built-in leakage absorption circuit zoo heev txo cov hluav taws xob poob siab rau tib neeg lub cev thaum cov khoom siv vaj tse raug them.

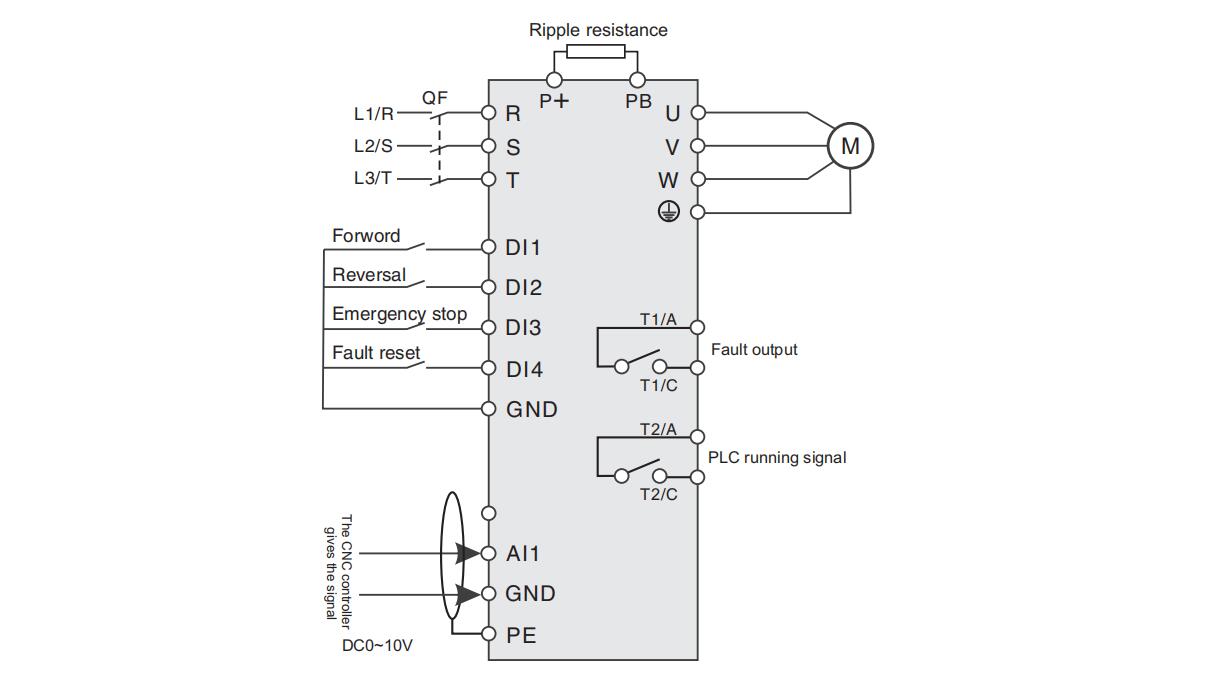

Basic wiring diagram

Parameter Chaw thiab piav qhia

| Kev teeb tsa Parameter | Cov lus qhia | Kev teeb tsa Parameter | Cov lus qhia |

| P0-03=1 | Tsis muaj PG vector hom | P4-01 = 11 KW | Rated zog ntawm lub cev muaj zog |

| P0-04=1 | Lub davhlau ya nyob twg sab nraud pib lossis nres | P4-02 = 380V | Rated voltage ntawm lub cev muaj zog |

| P0-06 = 2 | Analog AI1 tau muab | P4-04 = 22.6A | Rated tam sim no ntawm lub cev muaj zog |

| P0-14 = 150 | Tshaj tawm ntau zaus | P4-05 = 50Hz | Rated zaus ntawm lub cev muaj zog |

| P0-16 = 150 | Kev khiav hauj lwm zaus txwv | P1-06 = 1435RPM | Rated lub cev muaj zog ceev |

| P0-23 = 1.0 | Lub sij hawm acceleration | P6-00 = 2 | Qhov tso zis txhaum cai |

| P0-24 = 0.8 | Lub sijhawm deceleration | P6-02=1 | Zaus converter hauv kev ua haujlwm |

| P5-00 = 1 | Kev khiav mus tom ntej | P5-01 = 2 | Inverted khiav |

| P4-01 ~ P4-06 lub cev muaj zog tsis tau thov sau kom raug | |||

Debugging tshwm sim

Nws tau raug pov thawj tias KD600 series high-performance vector zaus converter tuaj yeem ua tau raws li qhov yuav tsum tau ua ntawm lub tshuab twj spindle tswj. KD600 tau txais kev coj ua PG-dawb vector tswj hom, uas tuaj yeem tso tawm 150% torque txawm tias nyob rau hauv qis qis (tsawg zaus) ua haujlwm kom tau raws li cov kev xav tau ntawm cov khoom sib txawv, thiab tuaj yeem hloov tag nrho cov qauv rolling bearing spindle, thiab no spindle. qauv yog yooj yim, compact, thiab muaj peev xwm ua tau tiag tiag stepless ceev txoj cai. Qhov ceev ntawm no spindle yog tswj los ntawm ib tug sab nraud analog teeb liab los tswj cov zis zaus nyob rau hauv ntau yam txheej txheem (xws li Roughing, xov, thiab lwm yam) xav tau kev ceev sib txawv, nyob rau lub sij hawm no, tus lej tswj qhov system tuaj yeem tso tawm cov analog voltage sib txawv rau lub sijhawm. inverter kom ua tiav qhov sib txawv ceev, thiab qhov pib thiab nres teeb liab kuj yog tswj los ntawm cov lej tswj qhov system, uas txhim kho qib ntawm automation thiab txuas ntxiv lub neej kev pab cuam ntawm lub cuab yeej.

Post lub sij hawm: Nov-17-2023